Filtration Technology

Proper filtration selection is critical to ensure operator safety from potentially harmful odors, vapors and airborne particulate. When selecting a filter for your application, Mystaire® reviews the complete application to make certain the proper filtration package is selected. At our state-of-the-art facility in Creedmoor, North Carolina, Mystaire filters are manufactured to the strictest quality standards in the industry. Our filters have undergone thorough laboratory testing to ensure their capability to meet your application challenges.

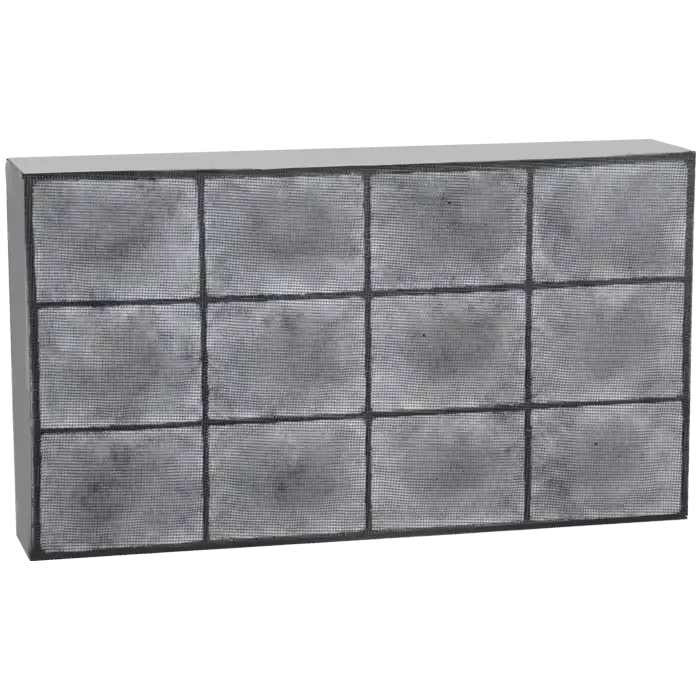

Activated Carbon Filters

Mystaire activated carbon air filters consist of high-grade coconut shell carbon. The steam activated nutshell provides a large surface area and an extensive internal pore structure for a high degree of adsorbency.

Chemisorptive Carbon Filters

To remove lighter weight gases that are not physically adsorbed by activated carbon alone, an impregnant is added to these filters. The impregnant utilizes chemical and physical attraction to enhance adsorption.

Multiple Application Filters

These filters are designed to remove a wide variety of contaminants. They are multi-layered filters according to general use or customized for special applications. For removing both chemical vapors and fine particulates, there is a special two-stage filter consisting of activated carbon (A/C) and HEPA.

HEPA Filters

High Efficiency Particulate Air (HEPA) Filters are available in various configurations for the containment of particles. The filter has a 99.997% efficiency rating for collecting 0.3 micron particles.

ULPA Filters

Ultra Low Particulate Air (ULPA) Filters are available in various configurations for the containment of particles. This filter has a 99.999% efficiency rating for collecting 0.12 microns.

Dual Purpose Safety Filters

The safety filter has been designed to incorporate both gas phase and mechanical phase filtration into one safety filter. The dual purpose safety filter is critical to ensuring operator and laboratory safety as it provides adequate reserve gas phase capacity as the primary filter(s) reach saturation.

Particulate Pre-filters

The particulate pre-filter is an electrostatically charged fiber filter which effectively removes submicron particulates. It is designed to protect the adsorption filter from contaminants such as smoke, acid mists, and other submicron particulates. All units are initially supplied with a pre-filter.

Removal Capacity of Standard Activated Carbon for Various Contaminant Vapors

Carbon is an effective medium to absorb chemical fumes and vapors. Filter life (also known as adsorption capacity) will vary with changes in the environment in which it is used. Below are the instances when carbon filter life or adsorption can be effective:

- Temperature: adsorption capacity decreases at higher temperatures

- Pressure: capacity becomes higher as system operating pressure increases

- Relative Humidity: capacity depends on type of contaminant. At higher humidity (RH >50%), capacity will be higher for water miscible solvents (Acetone, Methanol), but lower for immiscible solvents (Toluene, Benzene, Chlorinated solvents).

- Concentration: adsorption capacity improves with increases in contaminant concentration.

- Type of Contaminant: capacity generally increases for materials with a higher boiling point and molecular weight.