Types of Fingerprints

Fingerprints have been used for identification purposes for centuries. In fact, fingerprints served as signatures on clay tablets and seals in ancient China and Babylonia. Today, fingerprints are accepted as unique to each individual, meaning that no two fingerprints are exactly identical. Fingerprints can also be left or placed on almost any surface. Together, these two characteristics have made fingerprints an important part of forensic evidence collection. Currently, there are three types of fingerprints in forensic science: patent, plastic, and latent. Patent fingerprints occur visibly on hard surfaces and require no special technique to image. Likewise, plastic fingerprints are imposed onto malleable surfaces such as wax, clay, or blood and can be processed in a crime scene by photography. Latent fingerprints are the most challenging to identify of the three types because they are not visible and thus require specialized techniques to image and process as evidence.

Latent Fingerprint Development Techniques

Fingerprints are derived from components of sweat such as water, ions like sodium and chloride, lipids, proteins, and amino acids. Therefore, different chemical methods have been developed over time to image latent fingerprints based on interactions with a developing compound and amino acids and lipids within the fingerprint.

Fingerprint powders are composed of two classes of chemicals: pigments and binders. Pigments like be fine metal flakes such as aluminum, copper, or zinc provide color and/or contrast, while binders including rosin, gum arabic, and iron powder, are required to attach the pigments to the fingerprint lipids. However, fingerprint powders must be applied using a brush, which can potentially damage the fingerprint or transfer DNA to the surface. Therefore, other techniques have been developed to avoid these drawbacks.

Chemical imaging is a common method used for fingerprint development on paper and porous substances. In this method, a chemical called ninhydrin is mixed with alcohol to form a spray. The mixture is sprayed on the evidence, where the ninhydrin reacts with the amino acids in the fingerprint to form a purple-colored compound called Ruhemann’s purple. The purple color is easily visualized allowing the fingerprint to be photographed and subsequently analyzed.

Fluorescent methods utilize fluorescent compounds such as 1,8-Diazafluoren-9-one (DFO) to image the print under certain wavelengths of light. Similar to ninhydrin, the fluorescent compounds bind to amino acids within the fingerprint. When visualized under the correct wavelength of light, the compound fluoresces allowing the fingerprint to be visualized. However, the fluorescence is unstable and the print must be photographed quickly.

Cyanoacrylate fuming uses fumes from heated cyanoacrylate monomer or polymer glue. The fumes react with carboxylate groups in the amino acids and lactate found in sweat to form polymers that produce visible ridge marks on the evidence surface. This method is particularly useful for evidence with a textured surface, as powders and liquids can be difficult to remove from the ridges or crevices of an uneven surface resulting in a high background signal.

Vacuum metal deposition applies a mixture of gold and zinc atoms to fingerprints on surfaces. The metal atoms stick to the surface of the evidence, but not to the fingerprint; resulting in a sort of reverse fingerprint. This method is considered very powerful, but requires specialized equipment and training to complete.

Fingerprinting Safety and Contamination Prevention

Each of the fingerprinting methods described above has benefits and drawbacks, but also potential safety issues. Many of these methods utilize chemicals that may be harmful. When inhaled, fingerprint powders may cause respiratory irritation or lead to respiratory disease following repeated exposures over long periods of time. Some fingerprint powders also contain carbon black, which is considered a hazardous chemical by the Occupational Safety and Health Administration (OSHA). Therefore, precautions must be taken to limit occupational exposure to these powders to avoid exceeding OSHA’s permissible exposure limit (PEL). Though ninhydrin may be considered relatively safe, the alcohols within the spray are highly flammable and may pose a fire risk, especially if used in large quantities. Finally, cyanoacrylate fumes can irritate the skin, eyes, nose, and respiratory tract. Although these fumes are not considered toxic or carcinogenic, they can lead to allergic reactions in some individuals following repeated exposure.

To protect technicians or operators from potential hazards or noxious fumes associated with fingerprinting methods, individuals should utilize primary engineering controls specifically designed for fingerprinting procedures. The Downflow Latent Print Dusting Station is a great example of how to protect the technician from latent print powders. These workstations are designed to keep individuals from inhaling fingerprint powder, by drawing powder particles downward through the grated stainless-steel workspace or to the back of the hood where they are removed from the contaminated air using high efficiency particulate air (HEPA) filtration prior to air exhaust.

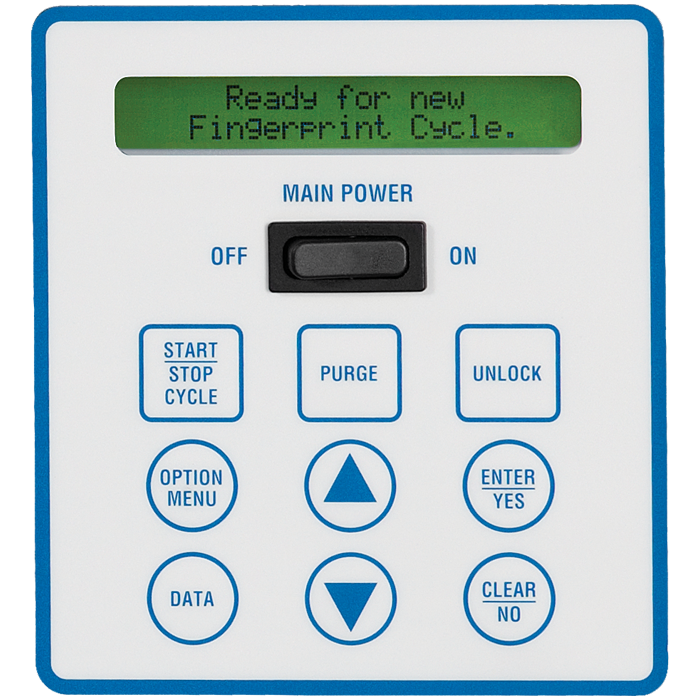

The safest and most reproducible method for cyanoacrylate fuming is to use a cyanoacrylate fuming chamber that automates the process. In these types of specialized chambers, the evidence for fingerprinting and the cyanoacrylate can be loaded into the chamber. The chamber is then closed and the automated fuming process can be started and completed without personnel exposure to noxious cyanoacrylate fumes. Mystaire’s Advanced Cyanoacrylate Fuming Chamber allows the evidence technician to set the fume cycle time and relative humidity via the simple-to-use microprocessor controller. Another benefit to this particular chamber is that air is then recirculated through a specially blended activated gas phase carbon filtration bed until the cyanoacrylate fumes are removed. This is unlike other chambers where the cyanoacrylate-laden air is recirculated back into the room. Fortunately, our patented method for capturing potentially harmful cyanoacrylate fumes is more effective than the single-pass filtration to guarantee the safety of your staff.

Other potentially hazardous chemicals, such as alcohols, should be handled in a ductless fume hood with a horizontal laminar flow. In these fume hoods, air is pulled from near the operator, across the workspace to the back and top of the hood. The contaminated air then passes through a carbon and/or HEPA filter to remove any contaminants prior to being exhausted into the room.

Even in the absence of hazardous chemicals, it still may be beneficial to conduct fingerprinting techniques within a ductless hood to prevent evidence contamination. Dust, debris, and cells from technicians or other samples can easily contaminate evidence leading to distorted fingerprints or DNA contamination. Working with evidence in a ductless laminar flow hood with a vertical laminar flow can help prevent contamination from the air and other environmental sources. In a vertical laminar flow hood, air enters through the top of the hood where it passes through a HEPA filter prior to reaching the work surface. The contaminated air from the work surface is then released through the front of the hood, near the operator. For this reason, ductless laminar flow hoods with a vertical airflow should only be used for non-hazardous applications, where operator protection is not a concern.